Technology processes in our company

Our company acquires a variety of secondary processes which provide an opportunity to get high quality of manufactured parts.

Vibratory Finishing

Barrel finishing – a technological process of mechanical operation of the parts, surface cleaning and surface pre-treatment of the parts made of: metals and alloys, ferrous and non-ferrous metals and other materials.

Used for small workpieces and parts processing from the scale, rough edges, moulding sand; also for quality improvement of the workpiece surface, polish preparation.

Special machines are used for vibratory finishing. Relative motion of the part and abrasive prills is conducted by disorderly subversion of the tumbling medium throughout the part in consequence of vibration.

Vibratory finishing at our company provides surface undulation up to 0.4 Ra.

Polishing

Our company acquires manual and machine polishing.

Polishing provides high quality of the surface undulation and considered to be finishing operation.

Chromium or iron oxide compounds are used for polishing.

Polishing at our company provides surface undulation up to 0.16 Ra.

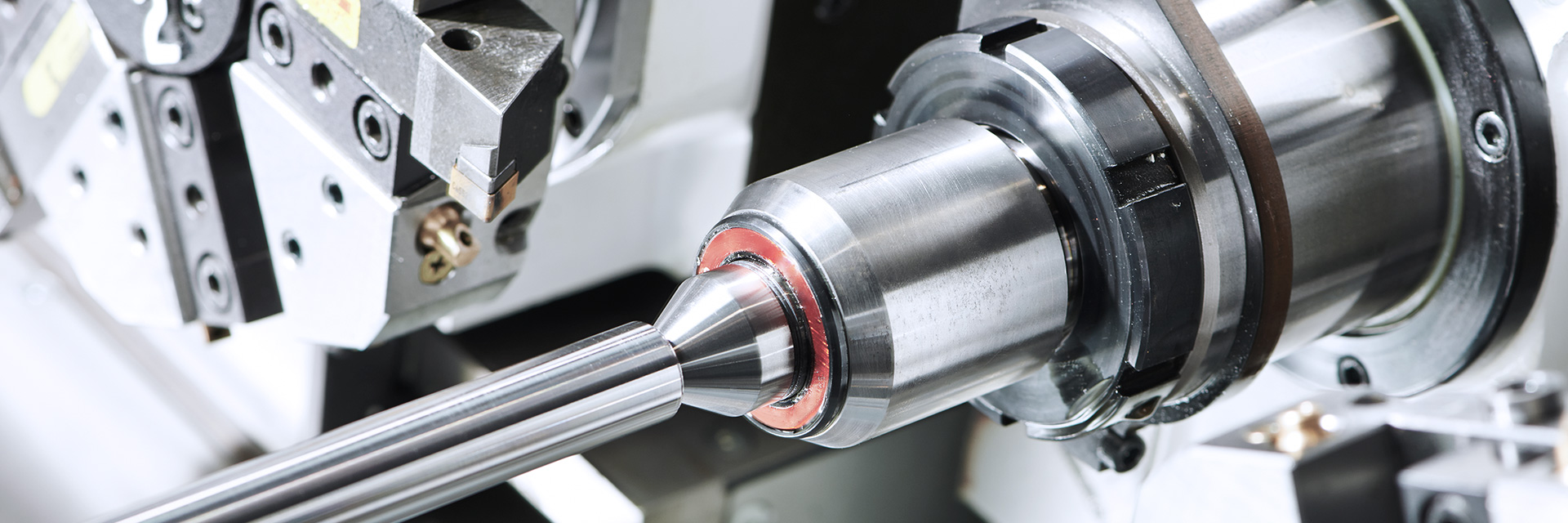

Diamond Burnishing

Diamond burnishing is used for the manufacturing of the high quality surface layer of the part and its performance characteristics amplification. Parts made of carbon, alloy and hardened differently steel, iron, aluminum alloys, bronze, brass and others are processed.

Diamond burnishing is a process of original microshape plastic deformation under the superposed force towards the diamond. Metal plastic deformation results in microridge smoothing of the processed surface and microshape filling of depressions by the size of distortional ridges.

Burnishing provides surface undulation: Ra = 0.08-0.32 mym, thereby cold-worked layer is formed, which depth is several tenth of mm, hardening degree is 40-200.

Diamond burnishing is used for shafts and rods processing, when it is needed to get high surface undulation and high surface mechanical characteristics. It scales up wear resistance, contact fatigue limit, corrosion-resisting properties, etc.

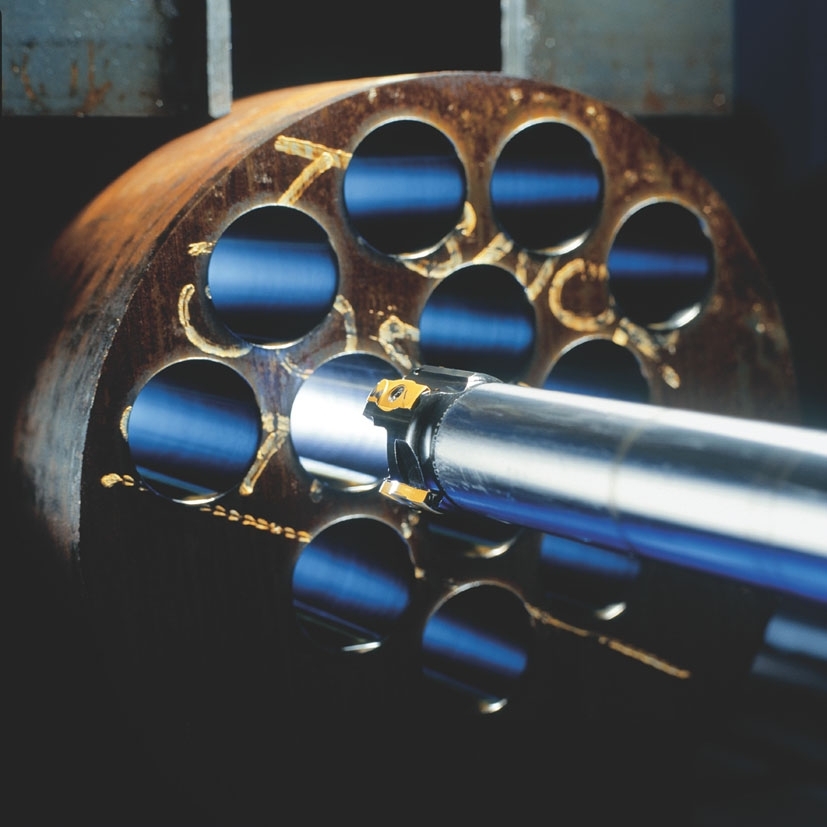

Deep Drilling

Deep drilling – a type of mechanical cutting operation, whereby special rotary cutting tool (a drill) provides holes fitting the drilled diameter to the depth up to 15d.

Deep drilling is conducted using machines by means of special drills and special tools with supply of high pressure lubricant coolant in a working zone.

Our company’s equipment provides the manufacture of the holes fitting the drilled depth to the length up to 30d.

Gas-shielded Welding

It’s all-position manual and semi-automatic welding, using ferrous and nonferrous metals and alloys up to tens millimeters thickness.

It provides high quality welding seam of ferrous as well as stainless steel, that is considered to be very important for pressurization. It provides a wide range of the weld material thickness – from the tenth to several tenth millimeters. Thermal influence zone is narrow, that prevents metal from the deflect.